Menu

Olympic Shipping has chosen Kongsberg Maritime’s new K-Walk integrated vessel gangway solution for installation aboard the Multipurpose Offshore Vessel (MPSV), Olympic Orion. Designed to significantly increase efficiency and safety for Walk-to-Work duties, K-Walk will be integrated with the advanced Kongsberg Information Management System (K-IMS) and the existing K-Pos Dynamic Positioning system on board Olympic Orion, which will be upgraded as part of the installation in the latter half of 2017.

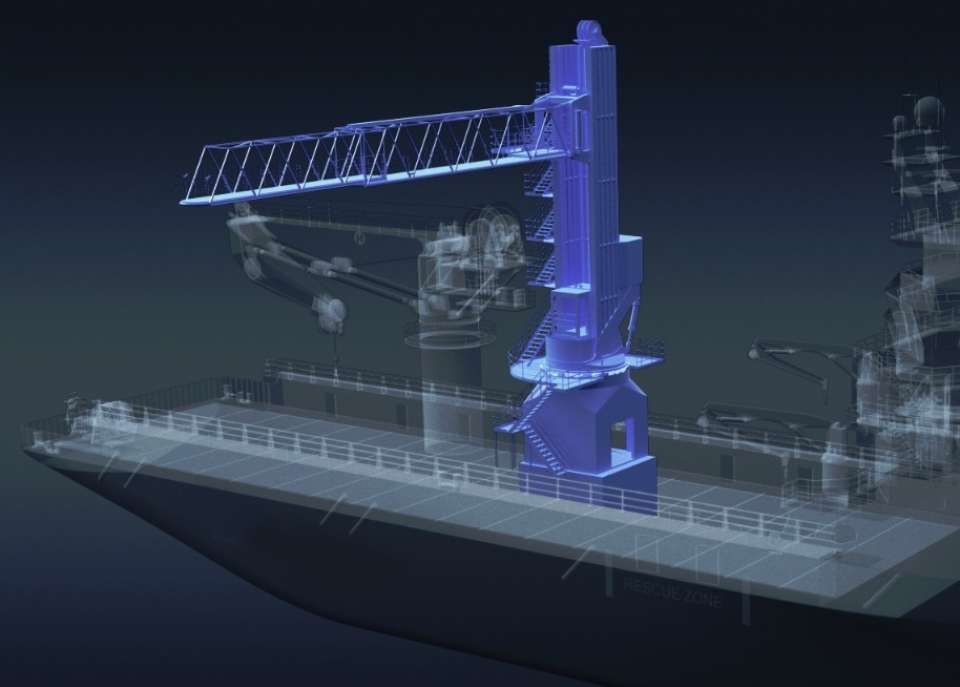

Olympic Orion will utilise the innovative K-Walk solution following its launch as part of KONGSBERG’s new Integration Strategy in Fall 2016. The system takes a new approach to increasing productivity and efficiency for Walk-to-Work vessels by improving operability of key systems on board. In addition to full integration with K-IMS to enable mission and route planning for increased service capability within a wind farm, the system interconnects with the DP and a planning station. The system extends vessel availability by increasing the operational weather window.

Through integrated mission planning, automated vessel manoeuvring and gangway hook-up, K-Walk introduces a step-change for increasing efficiency and productivity of the Walk-to-Work operations that are integral to Wind Farm Construction and Maintenance projects. While providing a completely safe, motion compensated gangway for the fast transfer of personnel and materials, integration enables more efficient approach and settlement at wind turbines and more effective logistics. The system is activated prior to entering a wind turbine’s safety zone, reducing vessel speed and launching the K-Walk hook up process during approach. Because of the integration with the DP, the gangway is able to move into position while the vessel is still moving, positioning it safely as the vessel arrives on station.

The integration of K-Walk with K-IMS is a unique approach that enables in-depth mission planning, resulting in increased productivity and efficiency by finding the most preferred route for increased service capability within the wind farm. The system will be fully connected with Olympic Orion’s DP system, offering increased operability with a new condition based operator environment, which requires less manpower and has minimal training requirements. The K-Walk solution for Olympic Orion will also improve time for mobility and safety with an integrated lift system for transfer of people and goods, including electric trolleys (under design) for movement of pallets across the gangway. Overall, K-Walk significantly enhances operational time efficiency, which improves productivity with the ability to serve more wind turbines within the same time frame.

“We are very satisfied to select Kongsberg Maritime’s new fully integrated Gangway solution for our MPSV Olympic Orion,” says Bjørn Kvalsund, COO, Olympic Subsea. “We also see a potential to install this integrated Gangway solution on board several of our existing vessels in order to provide W2W services into an expanding and interesting market segment.”

“Olympic Orion embodies the future that we envisioned with the launch of our Integration Strategy last year and we are delighted to work with Olympic Shipping for our cutting-edge new K-Walk solution,” said Stene Førsund, Executive Vice President, Global Sales and Marketing, Kongsberg Maritime. “K-Walk provides Olympic Orion with total oversight of route planning and gangway hook-up operations. It enables better real-time and long-term management decisions, and empowers safer, more predictable, and efficient operations through reduced human interaction and automation based on the deep integration of critical systems on board.”